TAKE THIS JOB AND

FORK-IT!

4D Pallet Shuttle AMR Solutions

Move IT 4K | Laser SLAM Autonomous Pallet Truck

Compatible with both closed and open pallets, unfazed by pallet types, offering flexible and seamless material handling solutions. Proficient in climbing slopes, overcoming obstacles, navigating elevators, mastering every task.

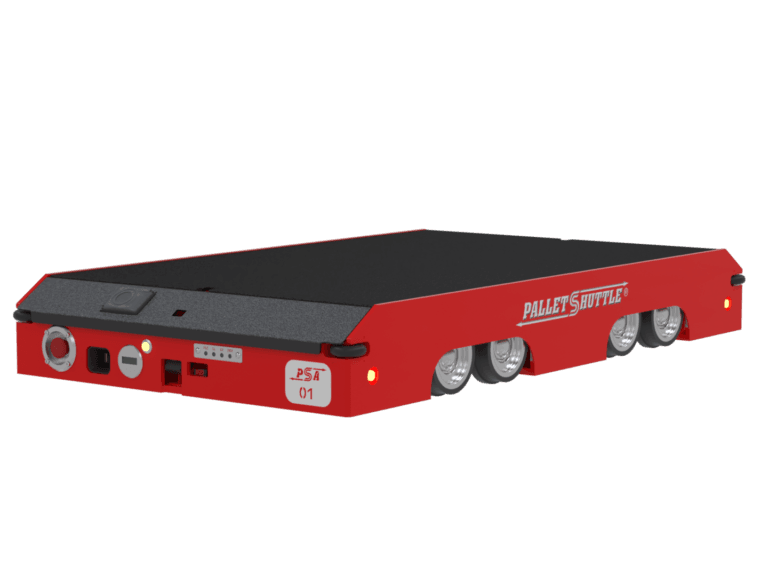

Heavy Duty 4D Pallet Shuttle Solutions Designed and Built in USA!

Pallet Shuttle 4 Directional units are built tough including direct shaft drive and heavy duty rack and pinion lift system. This unique design eliminates the need for belts, pulleys, chains and sprokets.

The Pallet Shuttle rack based HIGH DENSITY storage system interfaces with SmartLIft transfer units for full Dock to Stock processing.

Dock to Stock Autonomous Mobile Robot (AMR) Warehouse Solutions and Services

AMR Smart Lifts, Transfer Bots and Semi or Fully automated Pallet Shuttle ASRS systems team up to provide Dock to Stock and Goods to Person order processing.

Unload trucks at the dock and Pallet Shuttle takes it from there. Systems can be configued using SLAM, LIDAR, QR Code or NFL technologies.

Goods to Person Solutions

FLEXIBLE CONTROLLER AND SUPPORT SOLUTIONS

Controller Hardware

02.

Iterative Software Update Service

Software and hardware kit

04.

Model Selection Guide and Commissioning Manual

Training Courses and After-Sales Services

06.

implementation tool Roboshop Pro

AUTO INDUSTRY PROCESSING CASE STUDY

Professional Skill Development

FAW Volkswagen & FAW Logistics is engaged in the r&d and manufacturing of automotive electronic and components. Under the development of intelligent logistics, it is urgent to solve the problem of material transportation in warehouses and workshops

Solution Components

Laser SLAM smart handling forklift Roboshop Pro one-stop implementation tool Automatic Charging Pile RDS Unified Resource Dispatching System

Implementation Result

Robots replace manual handling, freeing up manpower and greatly reducing the labor cost of the enterprise. It is effectively connected with the MES system to promote the automation and intelligence of the workshop.

Challenge & Solution

Challenge:The laser sensor used for navigation is installed at a high position, and it is difficult to detect an obstacle in a low position. Solution: Add additional laser scanners at low positions for safety protection through multi-sensors.

Industries Trends

Reduce Redundant Forklift Costs with AMRs and AGVs

Warehouse automation is no longer a futuristic concept; it’s a present-day necessity for businesses seeking efficiency,…

10 Clear Signs It’s Time to Automate Your Warehouse

Warehouse operations are at the heart of supply chain efficiency. However, as markets evolve and customer…

What Is a 2D Semi-Automated Pallet Shuttle?

When it comes to warehouse efficiency and storage optimization, businesses are turning to innovative solutions like…

Enhancing E-Commerce Fulfillment using ASRS Automated Solutions

E-commerce has become one of the fastest-growing sectors in global trade, and with that growth comes…

Pallet Shuttle Automation high density storage storage solutions.

Who We Are and Why It Matters Warehousing, manufacturing, and logistics operations increasingly rely on cutting-edge…

Lowering labor costs for the modern warehouse with vision based AGVs

Introduction Efficiency and flexibility are crucial in today’s fast-paced logistics and manufacturing sectors. Vision-based Automated Guided…

Future Automation for Smarter Warehousing

Warehouse automation and high-density storage solutions powered by Automated Guided Vehicles (AGVs) are transforming logistics and…

Pallet Shuttle or Drive-In Racking? How to Choose

When it comes to modern warehouse operations, efficient storage solutions are critical for optimizing space, reducing…

How To Choose The Right Automated Storage System

Struggling with limited storage space or ineffective warehouse management? Investing in an automated storage system could…

Pallet Shuttle Automation Partners with UNARCO

Unarco and Pallet Shuttle Automation Announce a Manufacturing Strategic Alliance for making 2D and 4D Storage…

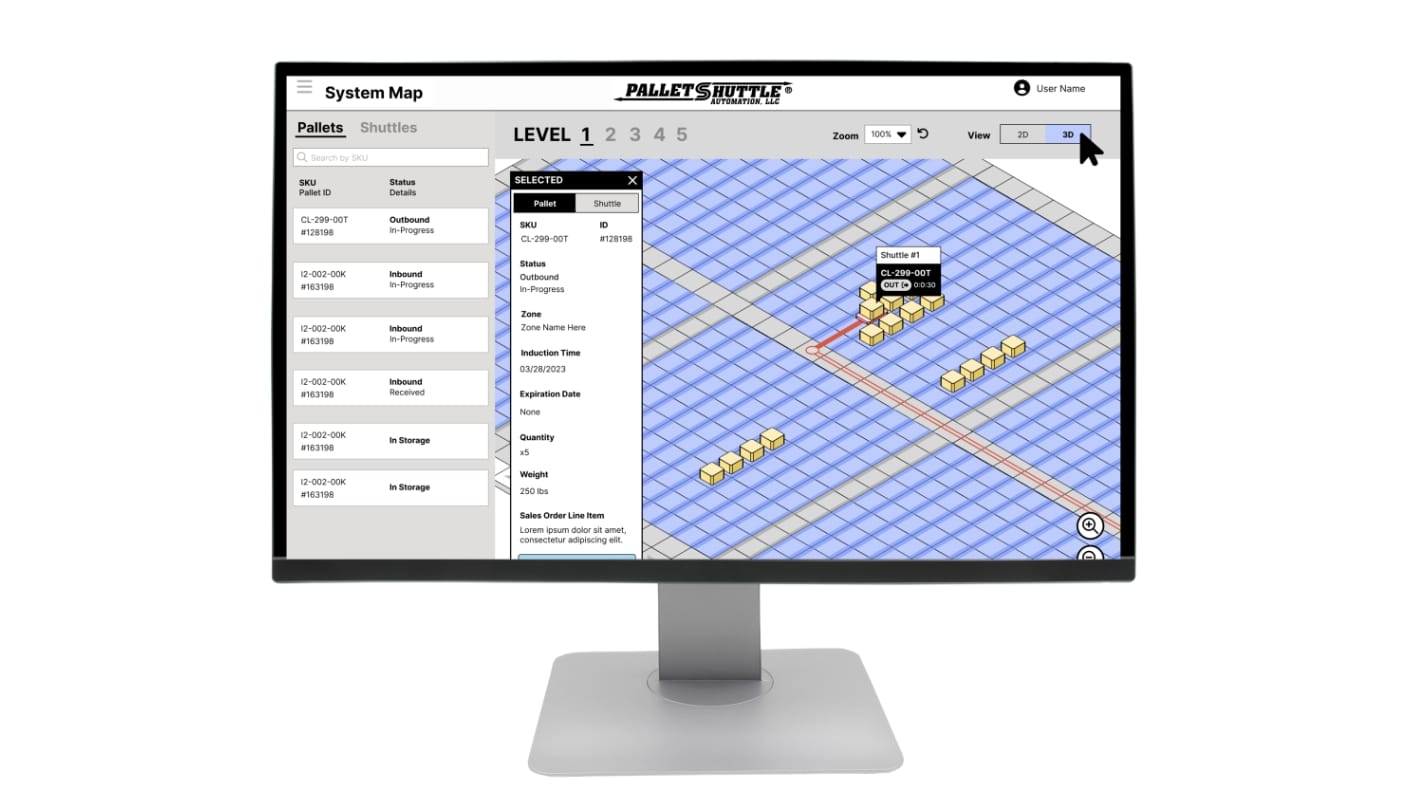

Pallet Shuttle Automation Partners with Avectous

Integrated Software to Deliver Next-Level Saas WMS and Robotic Control Solutions. NASHVILLE, TN – Pallet Shuttle…

Augmented Reality the Future of Training

The integration of Virtual Reality (VR) and Augmented Reality (AR) into vocational training presents a significant…