CONVERT YOUR FLOOR STORAGE TO SHUTTLE SPACE

Semi and Fully

Automated Pallet Shuttle systems

Semi and Fully

Automated Pallet Shuttle systems

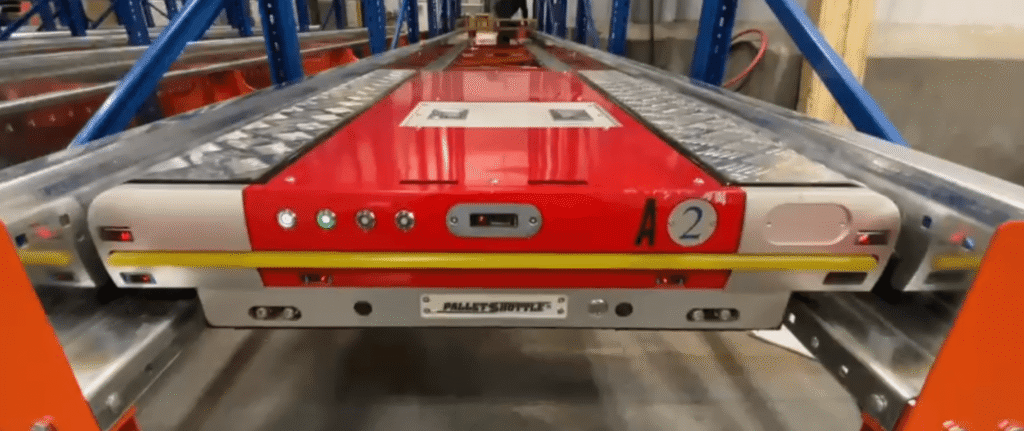

Bulk storage using floor stacking, drive in or pallet flow is highly labor intensive. Pallet Shuttle systems greatly reduce labor and redundant forklift operations.

Lets engage in a productive conversation. You can book a 30 minute discovery call with our design team to review feasibility and budget.

Application Videos

Production Plants

Manufacturers in all industries are challenges to store and track materials from receipt to production.

Pallet Shuttle systems can be utilized in raw material and finished goods areas for accurate inventory tracking.

E-Commerce

Direct to consumer order processing needs are growing as online shopping continues to replace legacy retail.

Pallet Shuttle 4D provides Dock to Stock and Goods to

person storage and processing solutions.

Food and Beverage

The food and beverage industry can increase storage capacity and reduce labor using Pallet Shuttle 4D technology.

Using high density Pallet Shuttle storage replaces floor stack reducing product damage and forklift needs.

Layer Picking

The food and beverage industry can increase storage capacity and reduce labor using Pallet Shuttle 4D technolgy.

Pallet Shuttles combined with mobile robots provides fully automated layer picking without conveyors.

Design and Implementation Services

Pallet Shuttle services offer a range of benefits for warehouse and manufacturing operations.Our design and implementation services ensure that each project is completed professionally.

Enhanced Storage Capacity

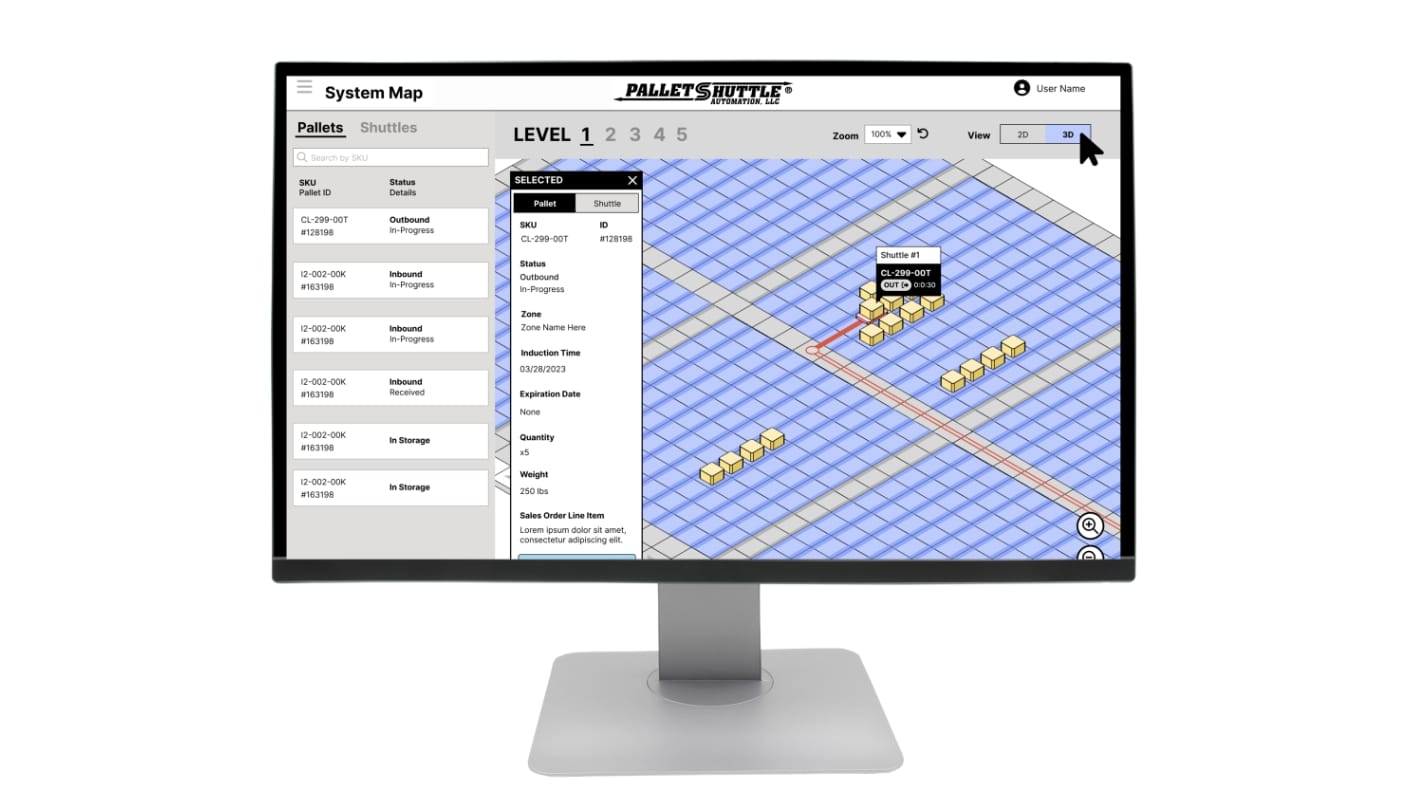

Streamlined Inventory Management

Reduced Forklift Requirements

High Density Storage Design and Planning Services

The Pallet Shuttle design team has over 30 years of warehouse design experience.

Schedule a design meeting with our design team for budget and feasibility.

Custom Product Design and Manufacturing

Our design team utilizes state of the art 3D design from concept to manufacturing.

All systems can be customized for special sized product and product weight.

Project Management and Installation Services

The Pallet Shuttle dedicated installation team ensures accurate installation.

Managing each project from from design to installation is critical for ASRS systems.

Frequently Asked Questions

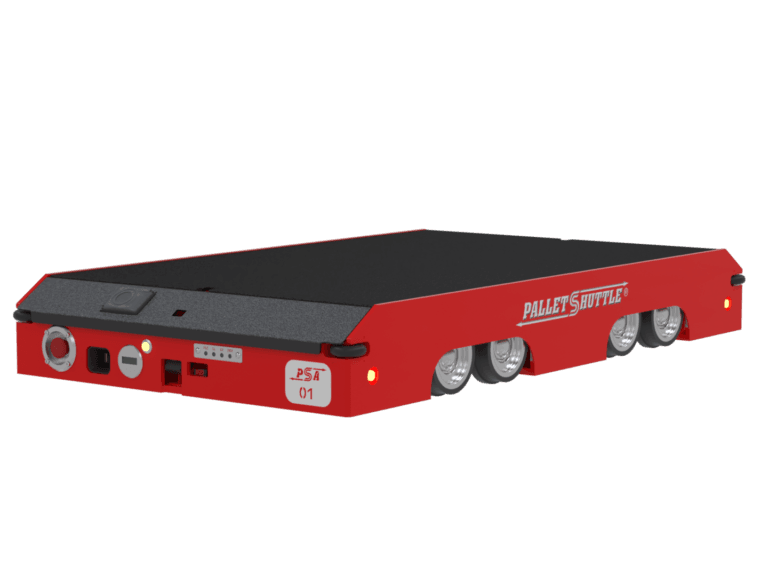

Autonomous robots are machines equipped with sensors, processors, and AI algorithms that enable them to operate and make decisions without constant human intervention. They can navigate their environment, perform tasks, and adapt to changes autonomously.

Autonomous robots have a wide range of applications, including warehouse automation, material handling, agriculture, surveillance, exploration, delivery services, and manufacturing processes.

A fully automated Pallet Shuttle high density storage rack system consists of pallet rack components combined with running rails for robots.

The main benefits of using a density storage rack include increased storage capacity, improved organization, reduced footprint, and better inventory management. These racks are particularly useful in warehouses, distribution centers, and other facilities where space optimization is critical.

Industry News and Trends

Learn about trends in Pallet Shuttle technologies and automated warehousing solutions that can help streamline your business.

Take This Job and Fork-IT: Embracing Innovation in the Workplace

Pallet Shuttle’s Fork-IT AMRs and Automated storage helps reduce forklift labor with “Dock to…

Reduce Redundant Forklift Costs with AMRs and AGVs

Warehouse automation is no longer a futuristic concept; it’s a present-day necessity for businesses seeking efficiency,…

10 Clear Signs It’s Time to Automate Your Warehouse

Warehouse operations are at the heart of supply chain efficiency. However, as markets evolve and customer…

What Is a 2D Semi-Automated Pallet Shuttle?

When it comes to warehouse efficiency and storage optimization, businesses are turning to innovative solutions like…

Enhancing E-Commerce Fulfillment using ASRS Automated Solutions

E-commerce has become one of the fastest-growing sectors in global trade, and with that growth comes…

Pallet Shuttle Automation high density storage storage solutions.

Who We Are and Why It Matters Warehousing, manufacturing, and logistics operations increasingly rely on cutting-edge…

Lowering labor costs for the modern warehouse with vision based AGVs

Introduction Efficiency and flexibility are crucial in today’s fast-paced logistics and manufacturing sectors. Vision-based Automated Guided…

Future Automation for Smarter Warehousing

Warehouse automation and high-density storage solutions powered by Automated Guided Vehicles (AGVs) are transforming logistics and…

Smart Storage Decisions: How Pallet Flow And Pallet Shuttle Compare

Efficient warehouse management is built on the foundation of reliable storage solutions, particularly high-density pallet storage…

Unlock More Storage and Efficiency with a High-Density Pallet Shuttle System

The Importance of Efficient Bulk Storage Solutions Hiring dependable and skilled warehouse forklift drivers is becoming…

Push Back Racking Or Pallet Shuttle Systems? How To Choose

Efficient warehouse storage solutions have always been at the forefront of supply chain optimization. With increasing…

Pallet Shuttle or Drive-In Racking? How to Choose

When it comes to modern warehouse operations, efficient storage solutions are critical for optimizing space, reducing…

Pallet Shuttle Automation Partners with ICS

Pallet Shuttle Automation and ICS Announce Strategic Partnership to Transform Warehouse Robotics Maintenance Monitoring Nashville, TN…

How To Choose The Right Automated Storage System

Struggling with limited storage space or ineffective warehouse management? Investing in an automated storage system could…

Pallet Shuttle Automation Partners with UNARCO

Unarco and Pallet Shuttle Automation Announce a Manufacturing Strategic Alliance for making 2D and 4D Storage…

Take this Job and Fork-IT

Revolutionizing Manufacturing and Distribution Operations with Advanced Autonomous Counterbalance AMR Solutions In today’s fast-paced manufacturing and…

Pallet Shuttle Automation Partners with Avectous

Integrated Software to Deliver Next-Level Saas WMS and Robotic Control Solutions. NASHVILLE, TN – Pallet Shuttle…

Pallet Shuttle Automation Partners with Seer Robotics

NASHVILLE, TENNESSEE — Pallet Shuttle Automation, LLC, an innovator in 4D Pallet Shuttle technology, announces its…

Augmented Reality the Future of Training

The integration of Virtual Reality (VR) and Augmented Reality (AR) into vocational training presents a significant…